Very fast, high-strength adhesive

High-strength bonding

- Very high adhesion

- Viscoplastic adhesive with low foaming behaviour

Hardens quickly

Fast reaction time with high initial strength after just approx. 15 minutes.

Specific adhesion spectrum

Excellent adhesive bonding with a wide range of substrates such as marble, artificial stone, etc.

Can be sanded and painted over

Weather-resistant and ageing-resistant

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

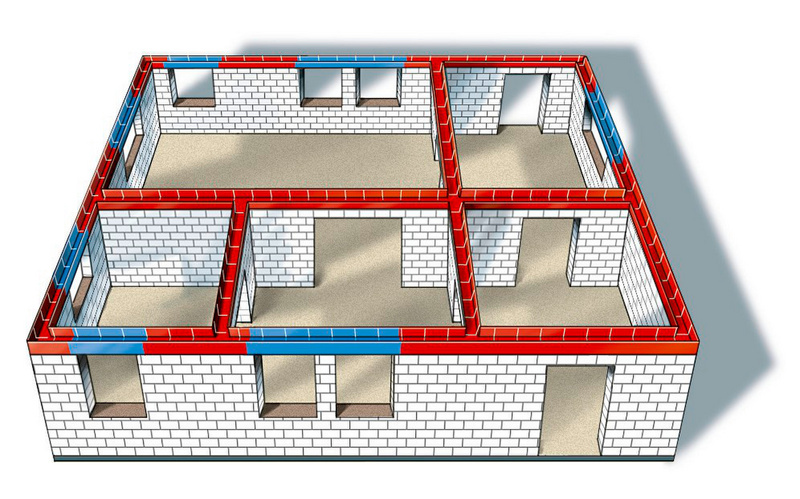

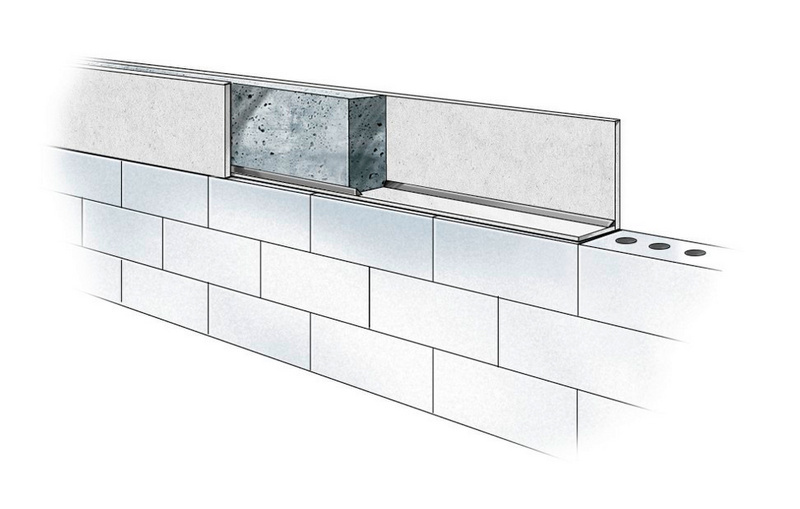

House door panels, stairway steps, handrails, lost box elements made of wood-cement flat pressed boards, baseboards, processing natural stone, metal window construction, window sills, laminated claddings, general repairs, and assembly connections. For adhesion of wood, metal, hard PVC, concrete, natural stone, laminated materials, ceramics, and hard foams (including those made from phenol resin and polyurethane).

Instructions

- The surfaces of the substrates to be glued must be dry and free of dust and grease. Remove any release agent that may be present. Depending on the material and the surface quality, the adhesive surfaces are pre-treated, sanded, cleaned with a non-oil replenishing cleaner, and a small amount of adhesive is applied. Priming the adhesive surfaces is recommended in some cases. For powder-coated surfaces and metal surfaces, pretreatment with cleaner type 60 (art. no. 0892130030) is recommended.

- The multi high-strength adhesive is applied to one of the bonded parts as a bead, or applied over the whole surface using the spatula. The adhesive is moisture-curing, i.e. when gluing non-absorbent materials or very dry materials to each other, the applied adhesive has to be additionally sprinkled with water to achieve complete hardening.

- The parts are bonded within a skin-forming time (max. 2 min. after wetting) and pressed together until functional strength is achieved. The amount applied should be around 150 - 300 g/m² , depending on the material.

Suitable glove:

Natural latex and neoprene chemical protective glove

Permeation level: 1

Cotton flocking on the inside

Permeation is the process by which a chemical moves through the material of a protective glove on a molecular level. The time from the initial contact between the chemical and the glove to the permeation of the material is the breakthrough time.

|

Measured breakthrough time

|

Permeation level

|

|

< 10 min

|

0

|

|

≥ 10 min

|

1

|

|

≥ 30 min

|

2

|

|

≥ 60 min

|

3

|

|

≥ 120 min

|

4

|

|

≥ 240 min

|

5

|

|

≥ 480 min

|

6

|

|

Important information:

The information given is based on experience and laboratory conditions and is designed as a guide. However, the actual suitability of a glove depends on the individual conditions of its use and must be confirmed by an appropriate test under operational conditions. Given the variety of materials and chemicals used, the possibility of incompatibility or usage problems for the wearer cannot be excluded in individual cases. We would be happy to advise you about optimum solutions.