Only for business customers

Customer Log in

Register your account

Sign up to become an online customer and start using all the features of our online shop!

Products

Exclusively for business customers

Hotline +374(0) 60 708807

Quick delivery

More than 125,000 products

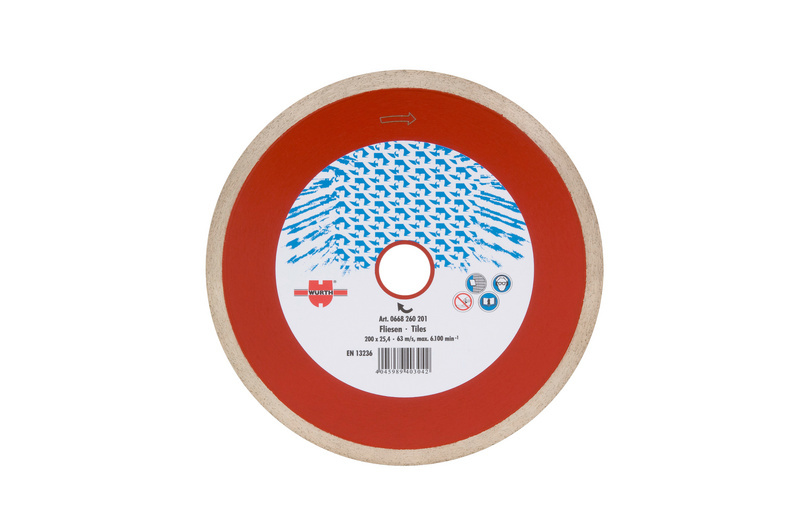

Related products

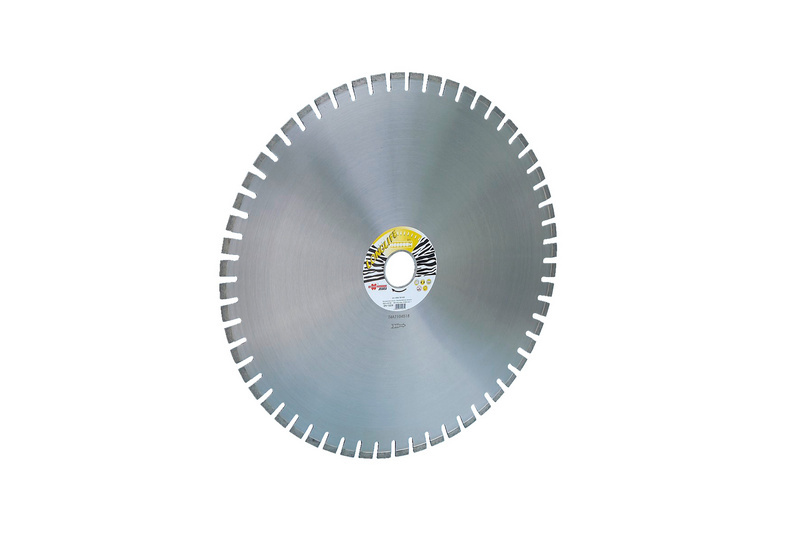

xDiamond cutting disc Long-life hard material

Code: 5526700180

Questions ? +374(0)10 349347, 349348

| 0x |

Please log in to see the price

|

Add to cart |

X-shape

The X-shaped ridges of the segment sides extend the service life considerably. They reduce the lateral contact surface of the segment in the material. This results in less friction and thus considerably less heat generation and strain on the segments. At the same time, the X structure increases the effectively active cutting surface, thereby distributing the load more evenly. The increased active cutting surface also enables comparatively quick cutting for a disc that offers an optimised service life.

Optimum bond for hard materials

The diamond bond is specially designed for hard materials and thus ensures optimum support for the diamonds from the first cut to the last.

Reliable direction indication

The ventilation holes are arranged as arrows that remain visible and unmistakable even after a long period of use.

- Diamond cutting discs become blunt at excessively high rotation speeds and wear too rapidly at insufficient peripheral surface speeds

- If ease of cutting is lost (indicated by heavy sparking), resharpen the disc in abrasive material, e.g. sandstone, with several cuts

- Cut larger workpiece cross-sections into several sections (swing cut)

- Work without applying pressure u2013 the weight of the machine is sufficient. Increased pressure causes increased wear.

- Diamond cutting discs are designed for straight cutting. Cutting curves deforms the blade and results in core cracks and segment tear-offs u2013 risk of injury!

- Despite the level of safety offered by the tool, always wear safety glasses and clothing while working

- Observe the information on the label (max. rotation speed), the restrictions of use and the safety instructions

- The direction arrow on the disc must match the machine's direction of rotation

- Must not be used for lateral grinding

- Use the appropriate protective hood

- Clamping must be performed only by a trained specialist (do not use force, use clean clamping flanges of the same size, perform a test run)

- If grinding tools are clamped or used incorrectly or are damaged, they represent a danger and may cause serious injury

LAST VIEWED