Only for business customers

Customer Log in

Register your account

Sign up to become an online customer and start using all the features of our online shop!

Products

Exclusively for business customers

Hotline +374(0) 60 708807

Quick delivery

More than 125,000 products

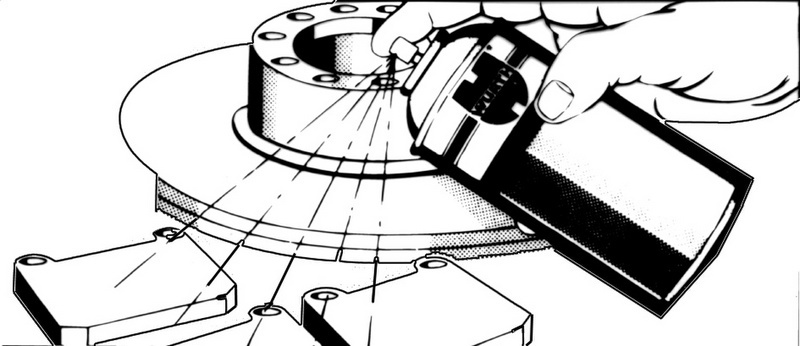

High-temperature lubricant paste HSP 1400

+374(0) 60 708807, +374(0) 10 349347

Tecnical Description

- Silicone-free: Yes

- Shelf life from production: 12 Month

- Smell/fragrance: Characteristic

- Contents: 300 ml

- Max. processing temperature: 40 °C

- Container: Aerosol can

- Min. temperature conditions: -40 °C

- Conditions for VKA welding load: in accordance with DIN 51350-4, VKA test (Institute for Internal Combustion Engines)

- Chemical basis: Mixed synthetic mineral oil with organic thickener and white solid lubricant combination

- Density: 0.973 g/cm³

- Min. processing temperature: 0 °C

- Max. temperature conditions: 1400 °C

- Min./max. friction: 0,1-0,13 µ

- Min. friction: 0.1 µ

- Max. friction: 0.13 µ

- Friction force: 450 N

- Friction force conditions: Friction cylinder/plate, 1000 µm, 50 Hz, 2 hours

- Load according to four-ball test: 3800 N

- Conditions for load according to four-ball test: in accordance with DIN 51350-4, VKA test (Institute for Internal Combustion Engines)

- VKA welding load: 4000 N

- Wear depth: 0.3 µm

- Resistance in salt-spray test: 500 h

- Conditions for resistance in salt-spray test: in accordance with DIN 50021

- VOC concentration (CH): 69.52 %

Chemical basis

Smell/fragrance

Density

Code

Package / Quantity

Price (AMD)

Mixed synthetic mineral oil with organic thickener and white solid lubricant combination

Characteristic

0.973 g/cm³

Code: 0893123

Product information

Catalogue page as PDF 1

Tecnical Description

- Smell/fragrance Characteristic

- Conditions for load according to four-ball test in accordance with DIN 51350-4, VKA test (Institute for Internal Combustion Engines)

- Min. temperature conditions -40 °C

- Min. processing temperature 0 °C

- Silicone-free Yes

- Conditions for resistance in salt-spray test in accordance with DIN 50021

- Conditions for VKA welding load in accordance with DIN 51350-4, VKA test (Institute for Internal Combustion Engines)

- VOC concentration (CH) 69.52 %

- Max. temperature conditions 1400 °C

- Shelf life from production 12 Month

- Wear depth 0.3 µm

- Chemical basis Mixed synthetic mineral oil with organic thickener and white solid lubricant combination

- Max. processing temperature 40 °C

- Container Aerosol can

- VKA welding load 4000 N

- Friction force 450 N

- Contents 300 ml

- Load according to four-ball test 3800 N

- Min./max. friction 0,1-0,13 µ

- Density 0.973 g/cm³

- Resistance in salt-spray test 500 h

- Max. friction 0.13 µ

- Min. friction 0.1 µ

- Friction force conditions Friction cylinder/plate, 1000 µm, 50 Hz, 2 hours

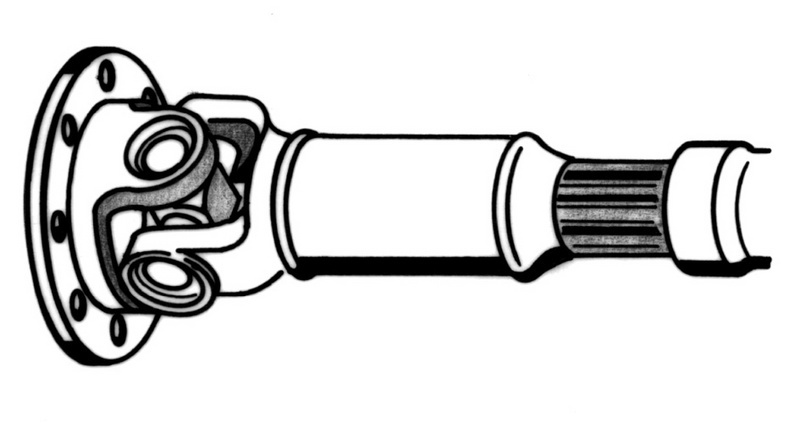

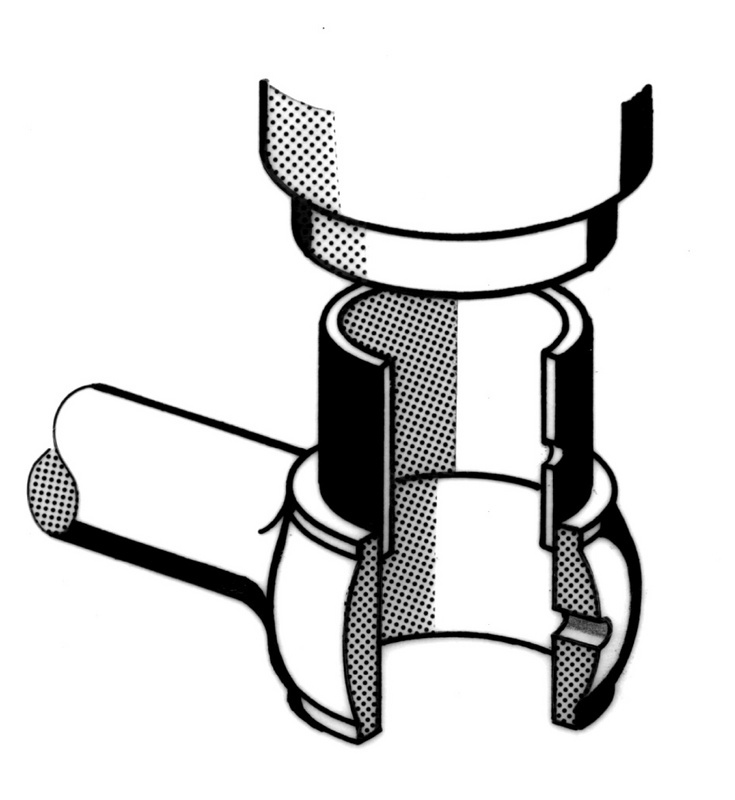

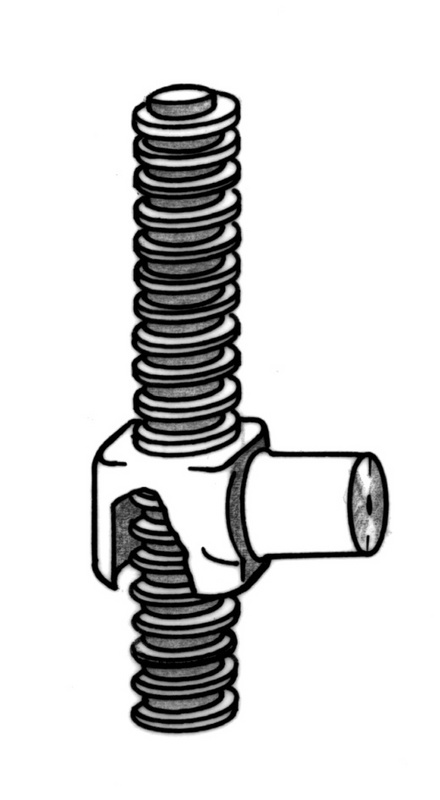

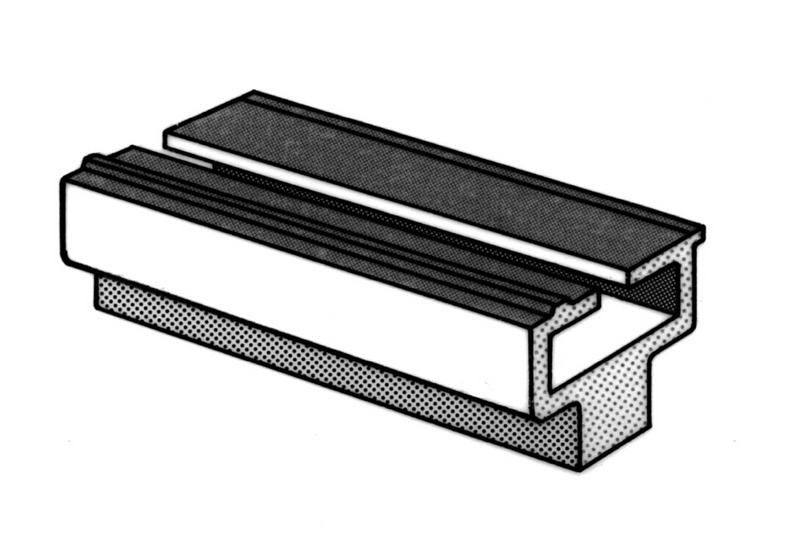

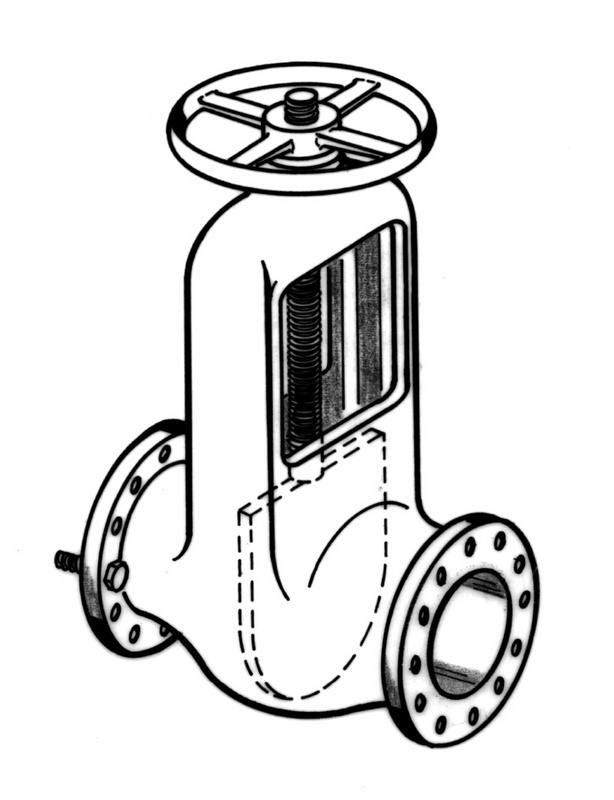

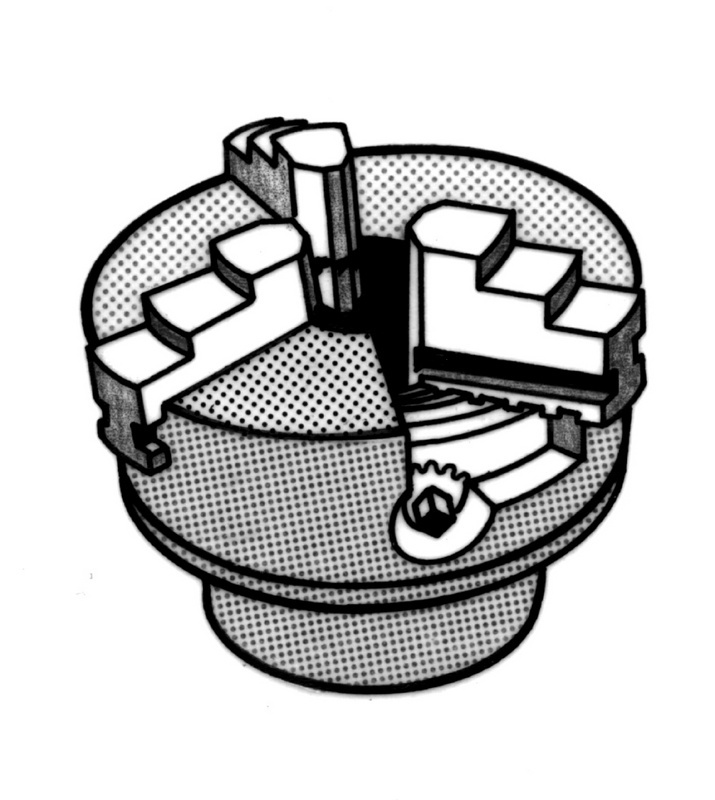

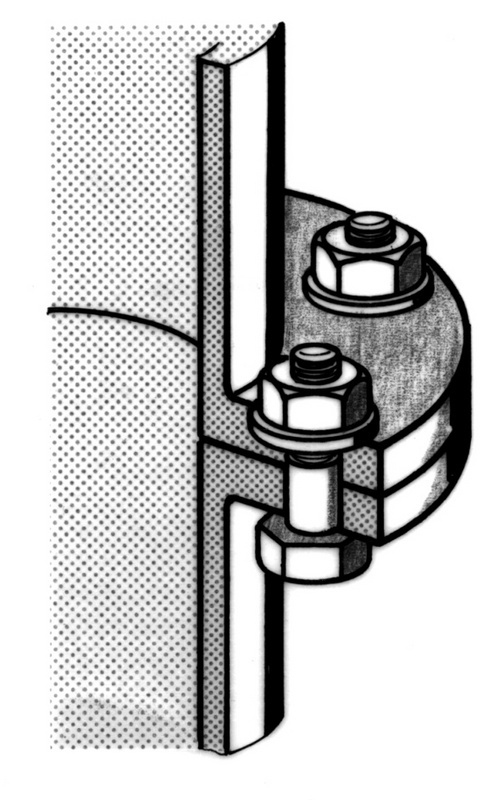

Grey, metal-free lubricant paste that reduces wear, separates surfaces reliably and provides outstanding corrosion protection.

Universal, pliable and highly-adhesive

Harmless to health

Non-toxic, no metallic pigments and free of graphite, MoS2 and sulphurous additives

Guarantees ease of movement and minimal wear

High compressive strength

Prevents corrosion, seizing and solidification

Guarantees uniform loosening of screw connections

Ideal as separating paste for stainless steel screw connections

Silicone-free

Notice

Not suitable for lubricating bearings

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Related products

LAST VIEWED