Only for business customers

Customer Log in

Register your account

Sign up to become an online customer and start using all the features of our online shop!

Products

Exclusively for business customers

Hotline +374 (0) 10 349347, 349348

Quick delivery

More than 125,000 products

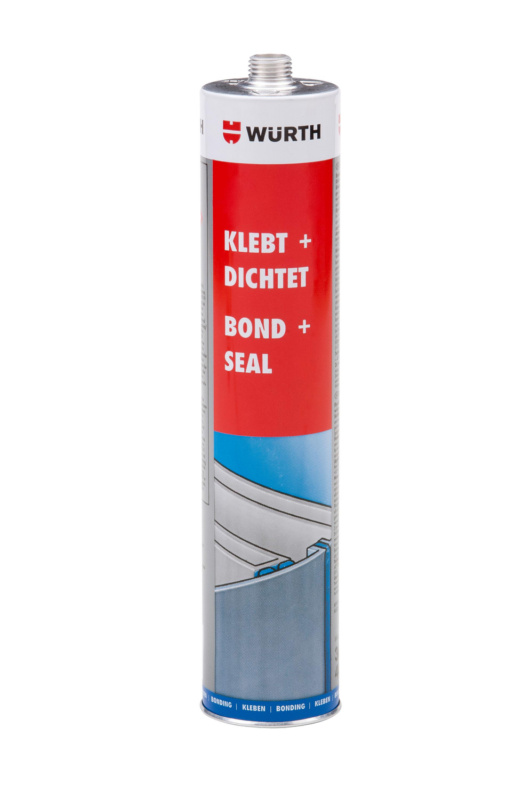

Welding spray Plus

+374(0)10 349347, 349348

Tecnical Description

- Colour: White

- Density: 1 g/cm³

- Shelf life from production: 12 Month

- Density conditions: at 20°C

- Container: Canister

- Chemical basis: Water tenside

- pH value: 8.6

Contents

Container

Chemical basis

Code

Package / Quantity

Price (AMD)

Code: 0893102005

Product information

Catalogue page as PDF 1

Tecnical Description

- Contents 5 l

- Colour White

- Container Canister

- Chemical basis Water tenside

- Density 1 g/cm³

- Shelf life from production 12 Month

- Density conditions at 20°C

- pH value 8.6

Code: 0893102020

Product information

Catalogue page as PDF 1

Tecnical Description

- Contents 20 l

- Colour White

- Container Canister

- Chemical basis Water tenside

- Density 1 g/cm³

- Shelf life from production 12 Month

- Density conditions at 20°C

- pH value 8.6

Prevents burning-on of weld splatter on metals, VA materials and on welding torch nozzles

Contributes towards optimum welding work. Starting points for corrosion are prevented

Cooling effect

Colour runs are reduced in VA welding

Silicone-free

Subsequent work, such as painting, is not adversely affected

Contents are identical to natural substances

- Free of hydrocarbons and other solvents

- The thin film simultaneously acts as temporary corrosion protection

Weld spray residues are easy to remove

Subsequent galvanising and painting pose no problem

REFILLOmatu00ae: Completely easy to use without flammable propellant

- Non-flammable

- High degree of work safety

- No label required

Release agents must always be applied sparingly. This is necessary to prevent the possibility of pores forming in the welded material or hydrogen-induced cracks occurring in sensitive steel under critical stresses.

Before galvanising, welding spray residues on the workpieces must be thoroughly removed with high-power assembly cleaner or a high-pressure cleaner.

This information is only a recommendation based on our experience. Preliminary testing required.

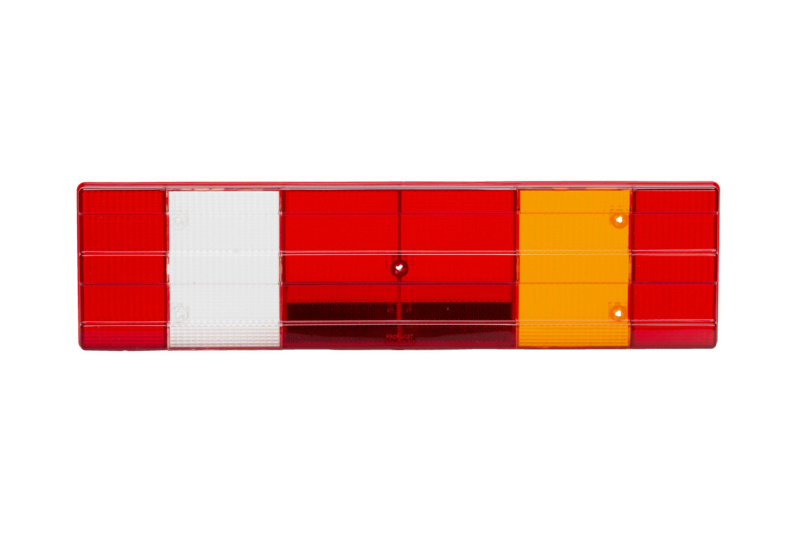

Related products

LAST VIEWED